DTG smarter. Not Harder.

Most DTG printers who print white T-Shirts just take a shirt and print. It is “just a white shirt after all ” – right? To keep the customer coming back you need to take the “long view” of quality while being profitable. Most “cheap” white shirts may appear to print good, but often times you have to increase the resolution and ink densities to achieve a really nice looking shirt. Some DTG printers do a double pass, or print the image twice, to achieve a nice dark looking print. This takes additional time and consumes twice the amount of ink. This will ultimately reduce the number of shirts you produce per hour BUT you will get better looking shirts.

Many DTG printers also have determined that they do not need to pretreat a white shirt. While in theory this is true the case is easily made that a pretreated white T-Shirt will appear more vivid, detailed and ultimately wash better than the standard, untreated shirt.

RTP Apparel garments were designed with our patent pending process in mind to help make the DTG printer more profitable while looking better. This means a DTG printer can print at a lower resolution on our white T-Shirt and usually achieve an equal or better looking finished shirt at higher production outputs per hour. For example, the same print on a Brother GT-3 printer running at 600 dpi will, in our example, take 1 minute and 05 seconds to print. The same exact print running at 1200 dpi will increase production time to 1 minute and 55 seconds. Just by printing at 600 dpi you can achieve approximately a 46% increase in the number of shirts you can print per hour. (see video below).

Math made easy. A spreadsheet to help understand.

You could ultimately pretreat the white shirt yourself but that will increase the workload, labor and material cost on a per shirt basis to achieve the same effects as an RTP Apparel garment. The appeal of the RTP Apparel white garments is that you can focus on what you do best – designing and printing shirts – not adding an additional step to your production process to gain a more acceptable shirt. RTP Apparel takes all of the additional work away.

We’ve developed a spreadsheet that allows any DTG user to input their own variables such as:

- The cost paid per white shirt

- The cost paid per RTP Apparel shirt

- The hourly rate for overhead, labor, other costs, and profit you charge per hour for your DTG printer.

- The output rate of the printer when printing on a standard White shirt to achieve the best output

- The output rate of running the same printer at a lower resolution to achieve the same or better output than the standard white shirt.

Download Spreadsheet

The spreadsheet will then simply break down the costs per hour and show you how much less/more per hour you could be putting into your pocket simply by running the DTG printer at a faster (lower resolution) setting when using RTP Apparel.

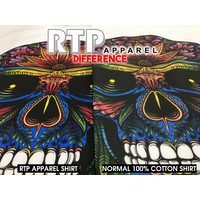

The video below shows the difference just printing at the same resolution on a standard white t-shirt versus printing on an RTP Apparel shirt. The quality difference is visibly apparent. The spreadsheet will then simply break down the costs per hour and show you how much less/more per hour you could be putting into your pocket simply by running the DTG printer at a faster (lower resolution) setting when using RTP Apparel. The video below shows the difference just printing at the same resolution on a standard white t-shirt versus printing on an RTP Apparel shirt. The quality difference is visibly apparent.

In addition to a better looking print, there is something to be said for the wash durability improvement that the RTP Apparel shirts will impart into your standard DTG prints. Most common DTG inks on the market will find better wash durability and longevity simply by being printed on RTP Apparel garments. You still print the same and cure the ink the same – nothing changes. The prints simply look and wash better. It adds up to better customer satisfaction and more repeat business. We understand that what we’ve been discussing here may sound like “sales-speak” to most people. For us at RTP Apparel we’ve been in the garment decorating business for over 30 years and have both pulled a squeegee and digitally printed shirts for a living – so we understand that it is often hard to believe a lot of what sales people say. However if you sit down and do the math it can be seen that what we are saying does work. We challenge you to test it for yourself. We know that on most standard size prints, like we’ve done on Brother and Epson printers that you can increase the number of shirts produced per hour which ultimately impacts your bottom line – in your favor.

Who doesn’t want to make more money per hour?